About

Project Summary

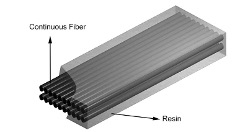

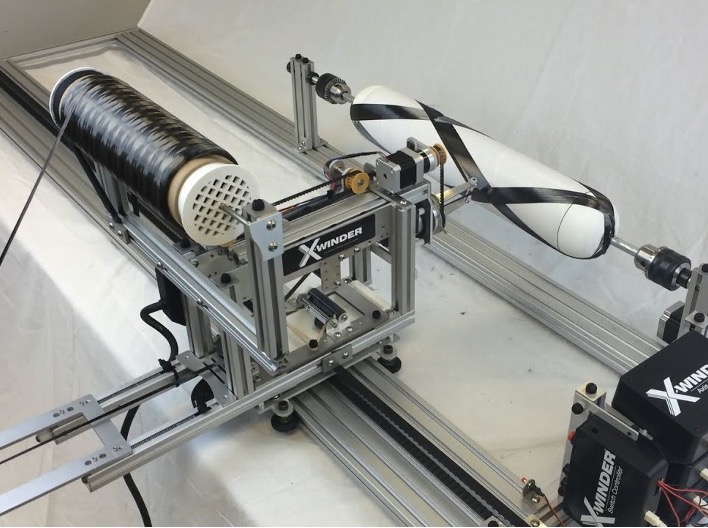

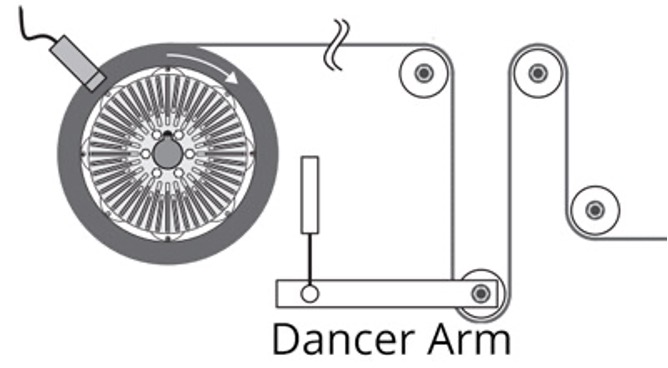

Composite Overwrapped Pressure Vessels (COPVs) are widely used in the aerospace field to improve the structural integrity of tanks holding high-pressure fluids. To manufacture COPVs, a filament winding machine is used. During the manufacturing

process, it is important to maintain a consistent filament winding tension to ensure that the wrapping strength is even across the surface area.

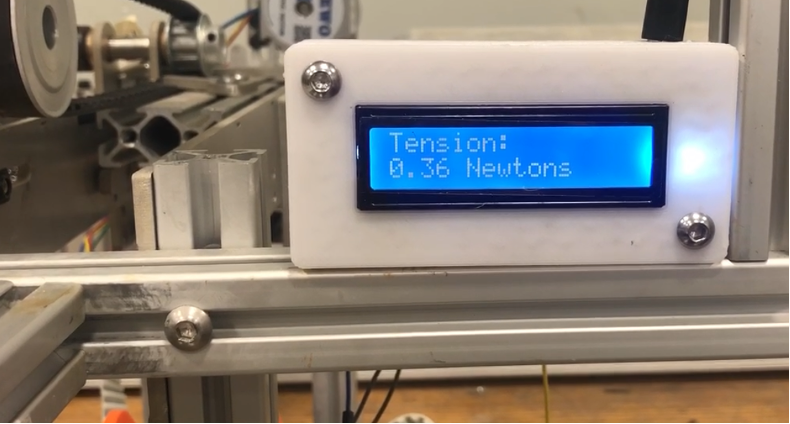

The objective of the project is to design, implement, and test a tension

measurement system that will detect, display, and plot the real-time tension to the operator, to improve the quality and repeatability of the produced COPVs.

Carbon Fiber Towpreg

Filament Winding Machine

Development

Conceptual Design

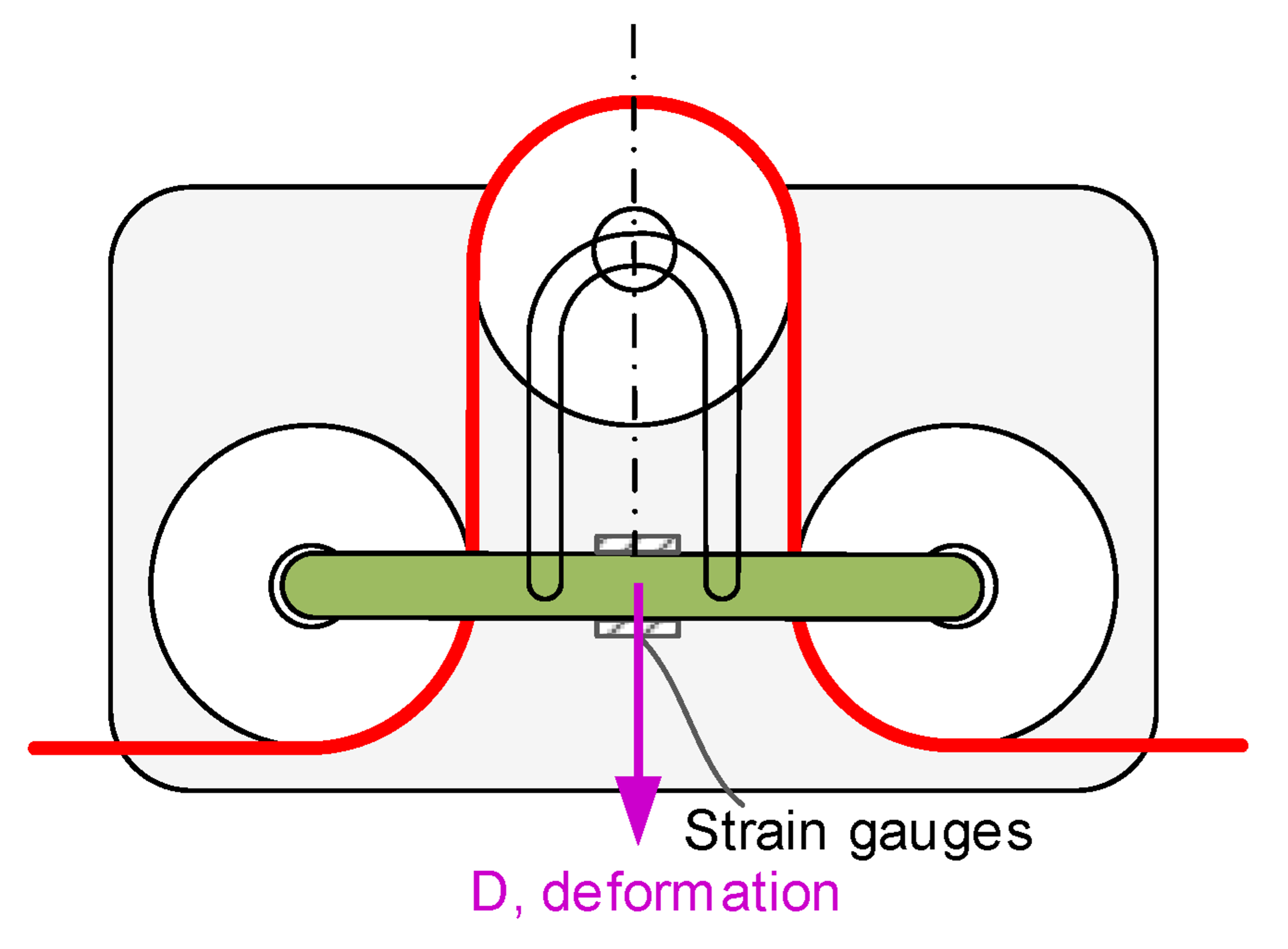

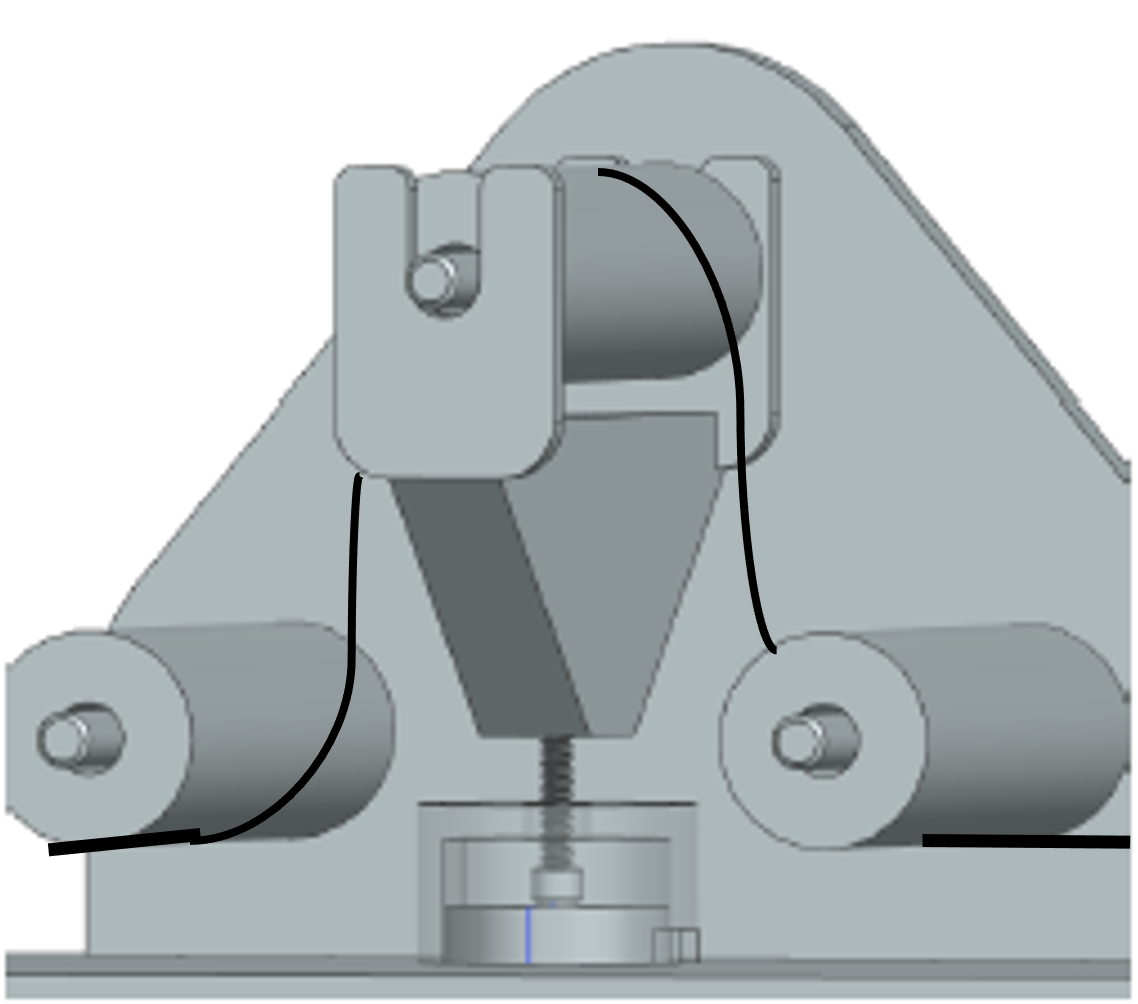

Multiple design concepts were evaluated prior to prototyping. By evaluating each with respect to the constraints and criteria, the configuration below to the right was chosen due to the simplicity, long-term robustness, and acceptable accuracy.

Development

Prototyping

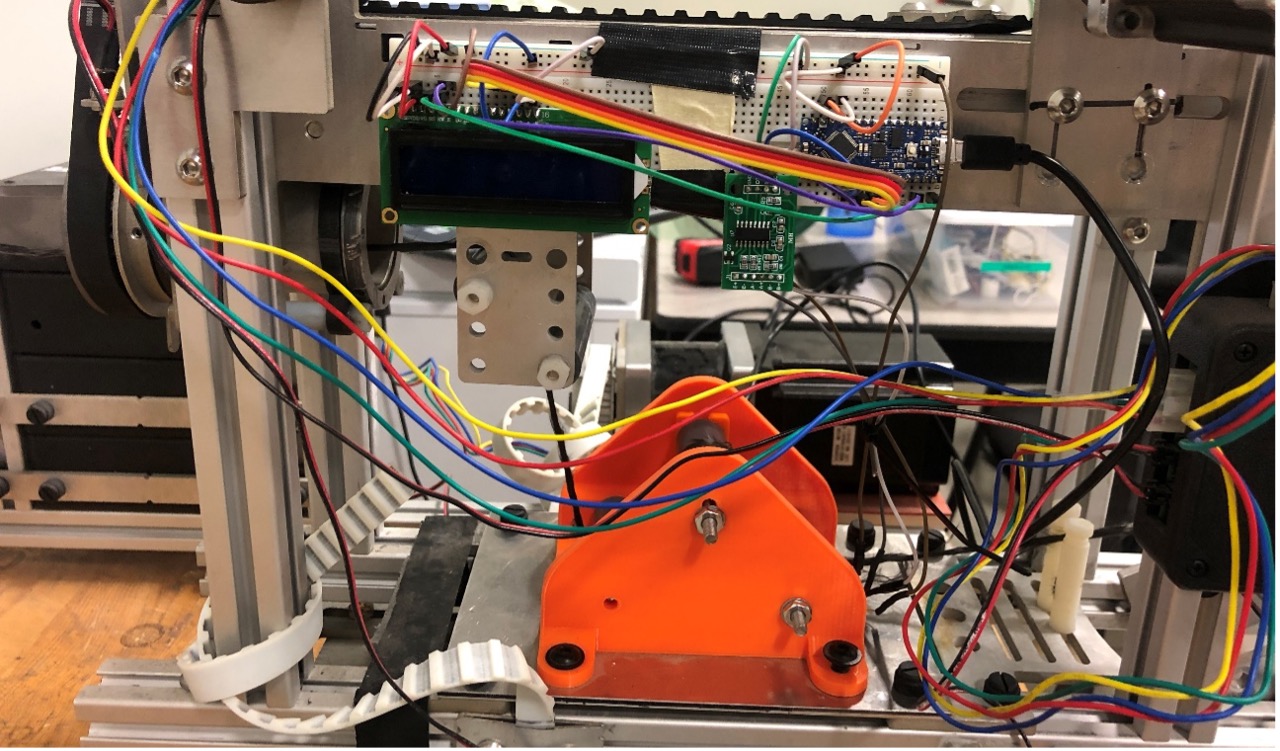

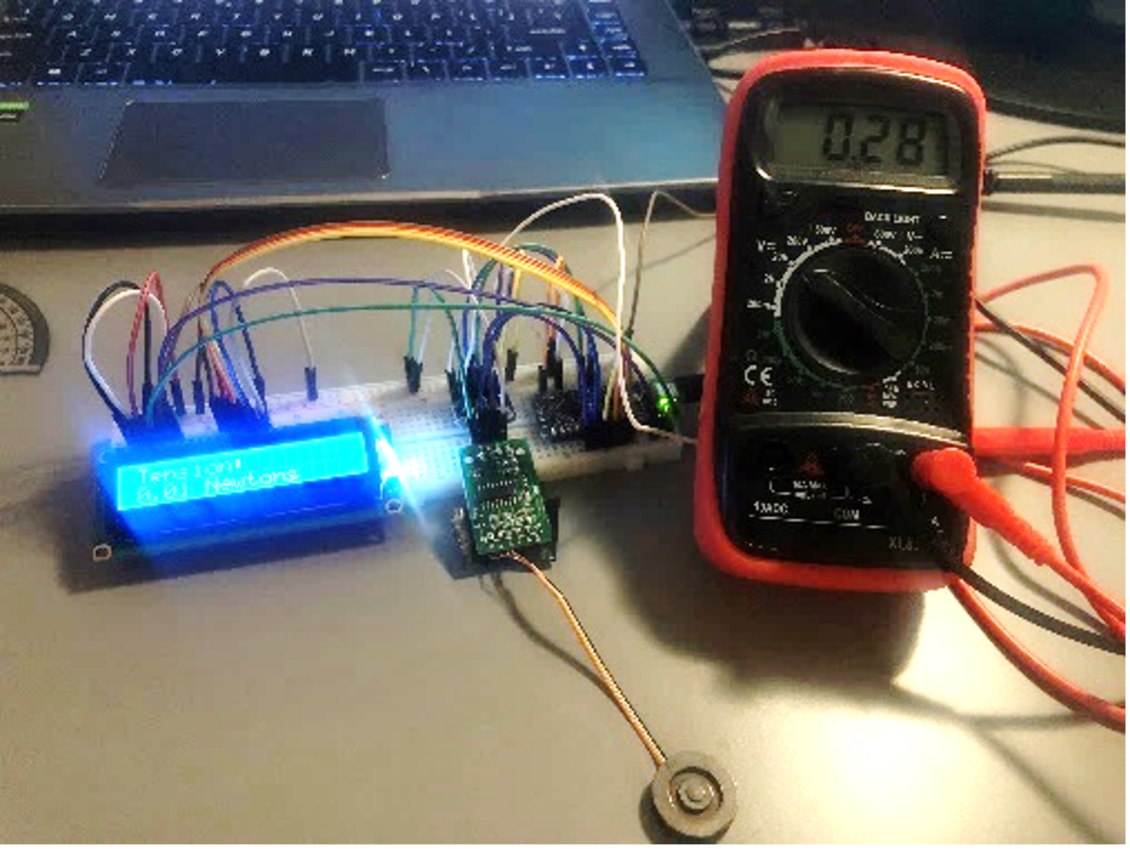

The prototyping can be divided into mechanical and electrical. The mechanical components were 3D printed and assembled with in-house hardware, and the electrical/sensor side was run on Arduino.

Calculations

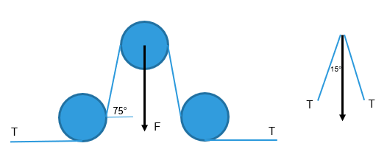

The trigonometric relationship between the rollers can be used to derive the tension force in the fiber.

Mechanical Design

As the tension in the fiber is increased, the center roller is pulled downwards on the load cell.

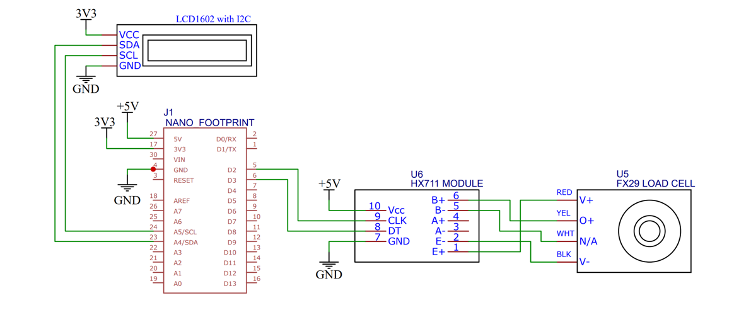

Electrical Design

The electrical architecture layout is included below. A low-cost SGA was interfaced with the Arduino to read from the load cell. The load cell was then calibrated within the desired load range.

Development

Final Design

The final design was then created and 3D-printed.